If you’re launching a career in process piping, you’ll probably encounter the concept of two-phase flow. With a Process Piping Certificate, you’ll be qualified to work with engineers and technologists, creating digital designs related to pipelines, pressure vessels, and process plant equipment. Equipped with knowledge of BIM and AutoCAD softwares, you’ll be able to develop and analyze designs which will effectively transport materials within breweries, food processing facilities, pharmaceutical manufacturing plants, water treatment facilities, chemical and petroleum processing facilities, and more. Once you’ve gained a solid understanding of the concept of two-phase flow, you’ll be able to effectively optimize the piping systems you design throughout your career, accommodating for the movement of different matters. Below, learn more about the concept of two-phase flow, and how it will apply to a brighter future in a process piping career.

What Is Two-Phase Flow? A Look for Process Piping Training Students

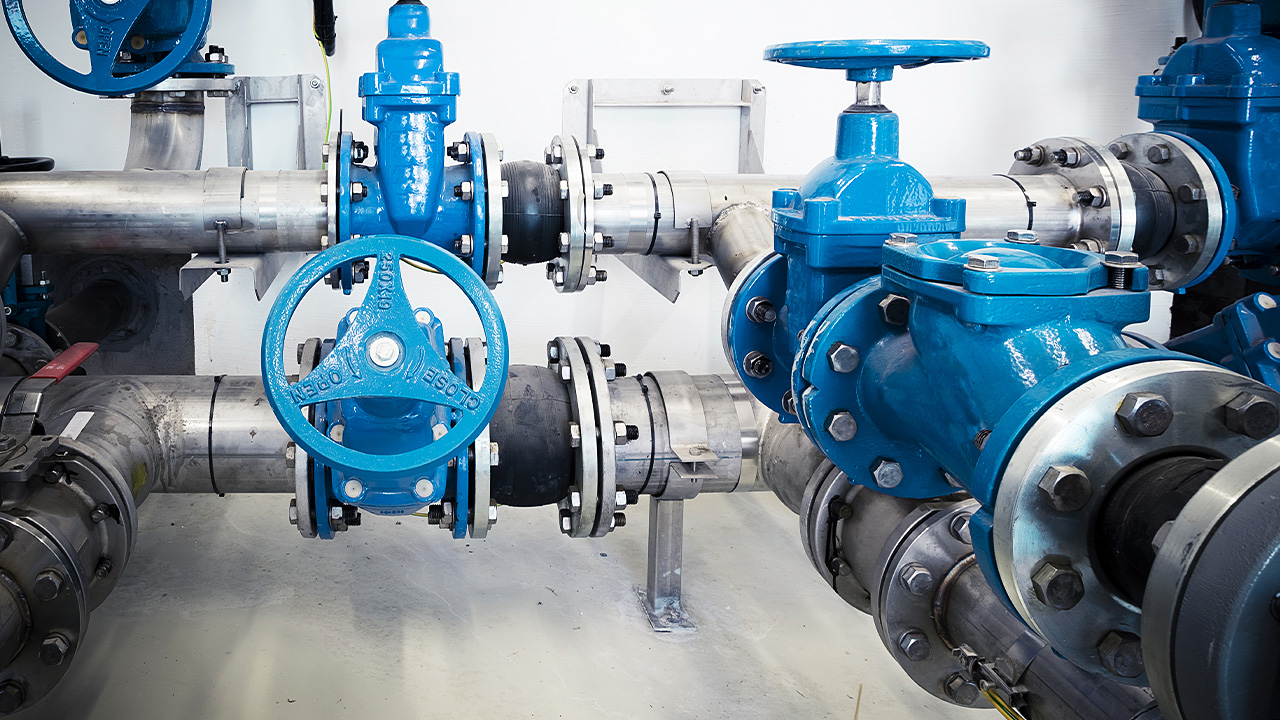

Two-phase flow is a concept that refers to the interactive flow of two different phases within a channel, tube, or pipe. A phase represents a certain volume or mass of solid, liquid, or gaseous matter, with distinct velocity, properties, and temperature. Within a two-phase flow, these different phases interact to create unique flow behaviors and patterns, which are the result of the competition of various forces such as surface tension, gravitational, and viscous. The result can lead to changes in the pressure and speed of the substances making their way through the channel. As a professional with process piping training, your understanding of two-phase flows will help you to effectively design systems which accommodate for chemicals, fluids, and other substances in different phases or states.

Within a two-phase flow, substances of different phases interact with each other

Types of Two-Phase Flows

If you’re launching a career in process piping drafting, it’s likely that you’ll be working with different types of two-phase flows, developing designs based on the behaviors of these flows. You may be creating designs for: 1. flows of solid-liquid, in which solid particles are transferred into a liquid substance, 2. solid-gas flows, where gas carries solid particles, or 3. liquid-vapor flows, where gas and fluid matter combine. A solid-gas flow might be seen in the transportation of grains, metal powders, coal, powdered cement and more, while a solid-liquid flow might be the flow of mud, slurries, or even of corpuscles within plasma. Of all the flow combinations, liquid -vapor flows are the most common within most processing facilities.

Vertical vs. Horizontal Two-Phase Flows

Within any process piping system, two-phase flows will behave differently depending on whether the pipe they pass through is vertical or horizontal. Within a piping system, the flow rate and flow quality depend on factors such as pressure and fluid, both of which change depending on whether the channel is horizontal or vertical. Within vertical channels, annular patterns are most common for liquid-vapor flows, as gravity forces the liquid toward the ways of the channel and the vapor through the center of it. However, in horizontal pipes, the liquid will drain toward the bottom, creating a pattern known as a stratified flow. This flow pattern can be changed if a significant force is applied, creating higher flow rates, thereby creating an annular flow. After getting your process piping diploma, understanding how fluid patterns are uniquely affected within vertical and horizontal channels will help you to develop accurate designs.