Natural gas has many uses, fuelling various industry processes as well as appliances in our homes. This can include anything from warming fireplaces and providing heat for cooking to fuelling power stations and providing electricity to various houses and company buildings.

Process piping systems make this supply possible, distributing natural gas from the supply source to homes and buildings in the service line. Here, gas flows from higher to lower pressure. Gathering pipelines extend from the supply source, branching out to various buildings in the service line. Transmission pipelines and distribution pipelines are also part of this system, allowing gas to move through as safely as possible. The moment when you take a process piping program, you’ll have the opportunity to discover the complexities of natural gas piping and the mechanisms of its transportation.

If you’re interested in specializing in process piping, read on for insights on industry techniques and best practices for transporting natural gas!

Relying on Strong and Durable Materials for Transporting Natural Gas

There are various materials used to make gas pipes, with the most common ones being steel, black iron, copper, polyvinyl chloride (PVC), high-density polyethylene (HDPE) and corrugated stainless steel tubing (CSST). Although the industry utilizes many of these materials, each area has its own standards for what is acceptable and what isn’t, especially when it comes to copper. Generally speaking, black iron is more commonly used due to its strength and heat resistance. However, it is susceptible to corrosion when not carefully maintained.

It’s important for pipelines to maintain their strength and durability over time, so various considerations are put into place. Pipe sections, typically produced in steel rolling mills, are specifically designed for their role in the pipeline. As a result, soil conditions and the location or population of the area may influence the pipe’s characteristics, which include size, strength, and wall thickness.

Coating pipes is another consideration that students in a process piping program may benefit from exploring. This step prevents the corrosion of steel pipes, which often involves deploying fusion-bonded epoxy coating or polyethylene heat-shrink sleeves.

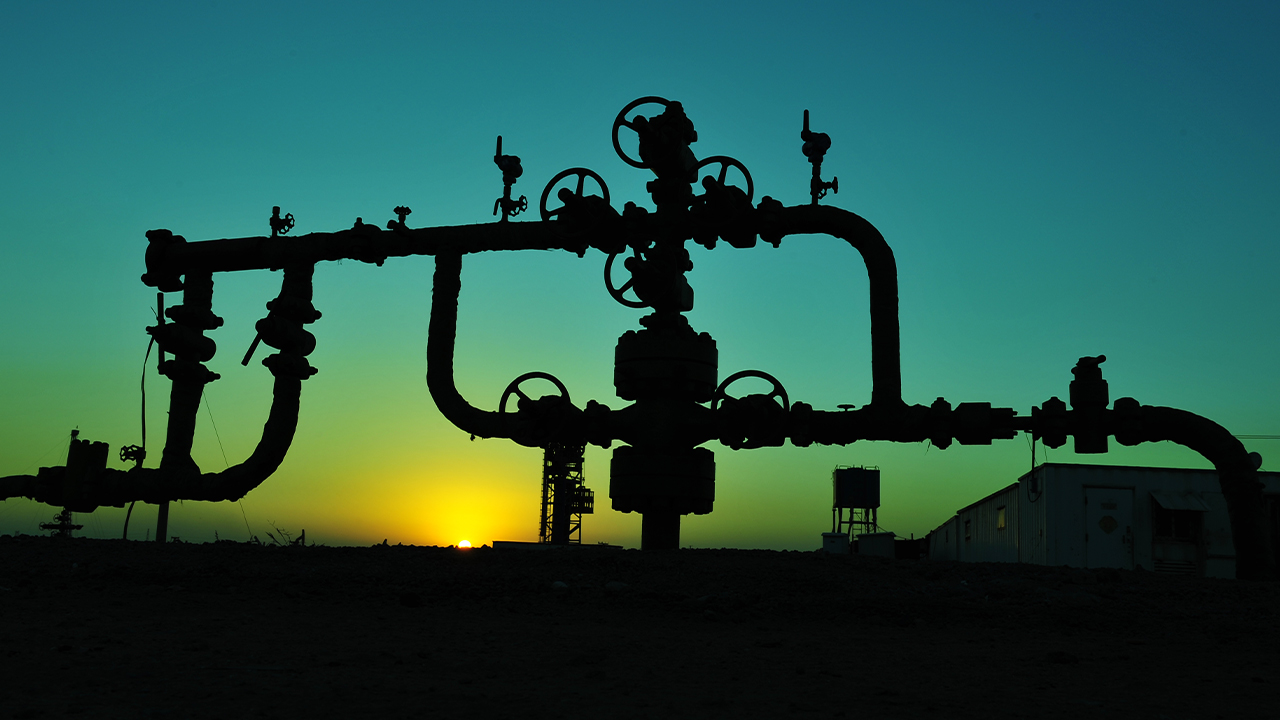

Industry professionals rely on different materials and techniques to ensure the safe transportation of natural gas

Installation Techniques Explored for Students in Process Piping Training

Many gathering and transmission lines are installed through the open trench method. However, pipelines may also be installed through a Horizontal Directional Drilling (HDD) method, which allows for underground tunneling or trenchless construction. HDD can reduce the environmental impact of these pipelines, but it should be noted that these pipes are placed at a certain depth to meet local guidelines and regulations.

Interestingly, many gas transmission pipelines are looped, running parallel to each other while following the same direction. This approach can increase gas storage in the system for better efficiency during peak periods. Students completing process piping programs online are able to learn key industry techniques to support the oil and gas industry, using their creativity and design skills to develop solutions and further the field.

Safety Concerns and Guidelines for Students to Consider

Students completing their process piping training may be keen to know about the safety concerns and guidelines surrounding gas piping. These can include poor air quality as well as potential fires and explosions when managed improperly. In addition to pipe coatings, industry experts may also rely on cathodic protection or corrosion inhibitors to prevent the deterioration of steel pipelines.

Other approaches include patrolling pipeline right-of-ways for leaks or construction activity, as well as odorizing pipelines. The latter approach gives the odorless natural gas a particular smell that makes any leaks easily detectable. As a result, industry experts are able to ensure the public’s safety while preserving the longevity of the materials in use.