In 2016, there were over 100 incidents across Canada in which petroleum products like natural gas and oil spilled out of pipelines. Many were minor, with relatively small amounts of the spill, but even small amounts can have damaging effects on wildlife and the environment. Beyond that, there can be risks to human health when vapours and other contaminants linked to petroleum products are released into populated areas.

Fortunately, researchers may have a solution. By introducing a new but very feasible design, they claim it is possible to more easily prevent spills, along with the costly cleanup that can be associated with them.

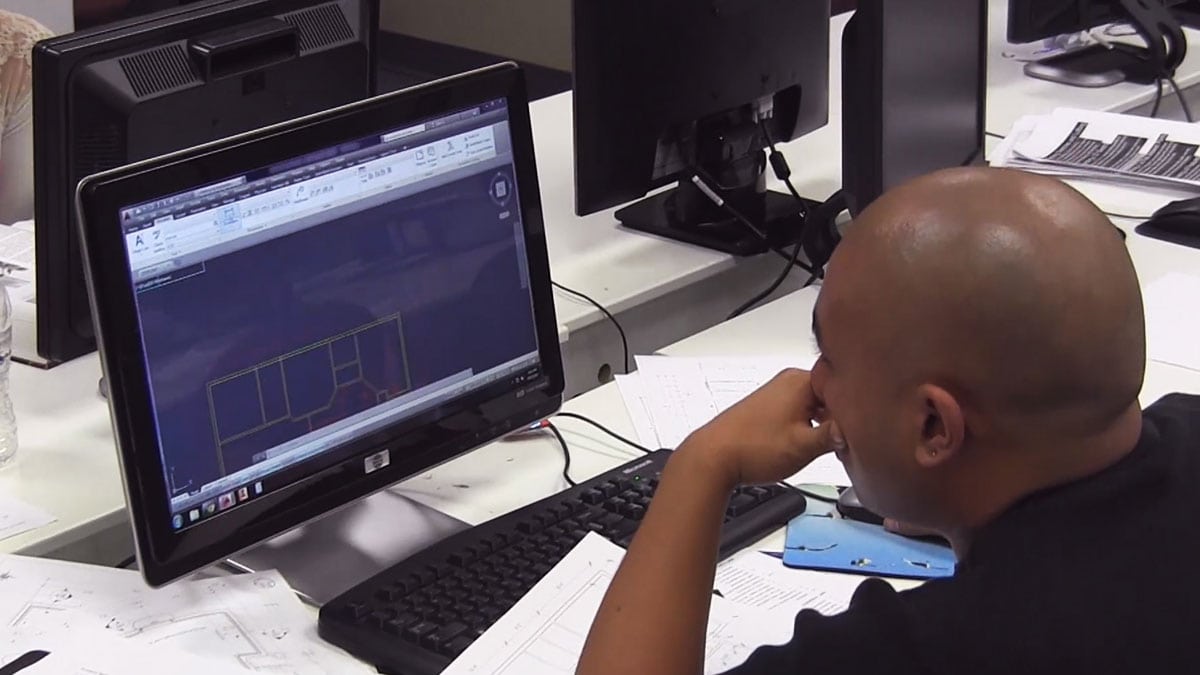

Here’s what students in CAD training need to know about this interesting new design.

The Proposed Solution to Spills: Multi-layered Pipelines

As a long series of tubes that transports liquids or gases between two points, a pipeline can be vulnerable to leaks. When a pipeline is damaged, it often happens that some of its product will flow out of the breach, similar to water leaking from a puncture in a garden hose.

The new design proposal hopes to eliminate the possibility of this happening in part by enclosing the pipeline inside of another layer of pipe. The innermost pipe would contain the product being transported, and the outer pipe would be like a safeguard. If something goes wrong with the inner pipe, the oil would spill into the next layer, keeping it contained and away from the environment.

It’s an interesting design concept, particularly for the CAD professionals who might one-day help model designs with this feature. Extra piping means extra weight and size, potentially requiring different choices for design or location for the pipeline. It would likely result in more complicated digital models, too. If this concept takes off, graduates of CAD courses might see it as an interesting challenge.

Graduates of CAD Courses Would Also See New Tech in the Design

Layering the pipelines in this way is only one part of a larger plan. Another important element to this spill-proof design is to include special sensors along the inside of the exterior pipe. These sensors would be set up to detect product leaking from the inner pipe, and would immediately send an alert to the owners to tell them where the leak is located, as well as how much product is being released. This allows for real-time monitoring, whereas current sensor technology is better equipped for detecting leaks after they have happened.

Process piping training at Digital School offers you the chance to learn many important skills, which you may one day use to design new pipelines. From fundamental skills in drawing and designing effective pipelines to using computer-aided design software to incorporate extra systems into a model, these skills could someday help you create many different pipelines. Who knows, you might even one day have the opportunity to include this new sensor technology into your designs.

Digital School can teach you the skills necessary for helping model high-tech pipeline projects

The Main Downside of This New Design: A Higher Cost

Extra materials and more advanced sensors will, by necessity, cost more money to implement in a pipeline than the more basic design we see today. Estimates are that this new spill-proof design will cost around 25% more to build than a regular pipeline would, meaning a significant expense for the company making it.

The researchers behind the project argue that the reduction in cleanup costs, and the potential to avert a large amount of negative press when spills occur, outweigh this price difference in the long run. Whether or not companies agree, and begin investing in spill-proof pipelines, will likely only be seen sometime into your CAD career.

Computer-aided design college is a great way to join the fascinating world of digital modeling.

Contact Digital School to learn more about signing up!