Offshore or subsea pipelines are important for the transportation of oil and gas to various areas via straits, rivers, and other larger water expenses. There are many factors that are taken into account whenever designing offshore pipelines, such as following international pipeline design codes and standards. It’s also essential for pipelines to be strong enough to contend with the threat of high temperatures, pressure, corrosion, earthquakes, and other dangerous seismic activity.

Graduates with diplomas in process piping have the skills and knowledge to help design teams craft pipelines of all kinds. Read on to learn more!

Routing Considerations Are Crucial to Offshore Pipeline Design

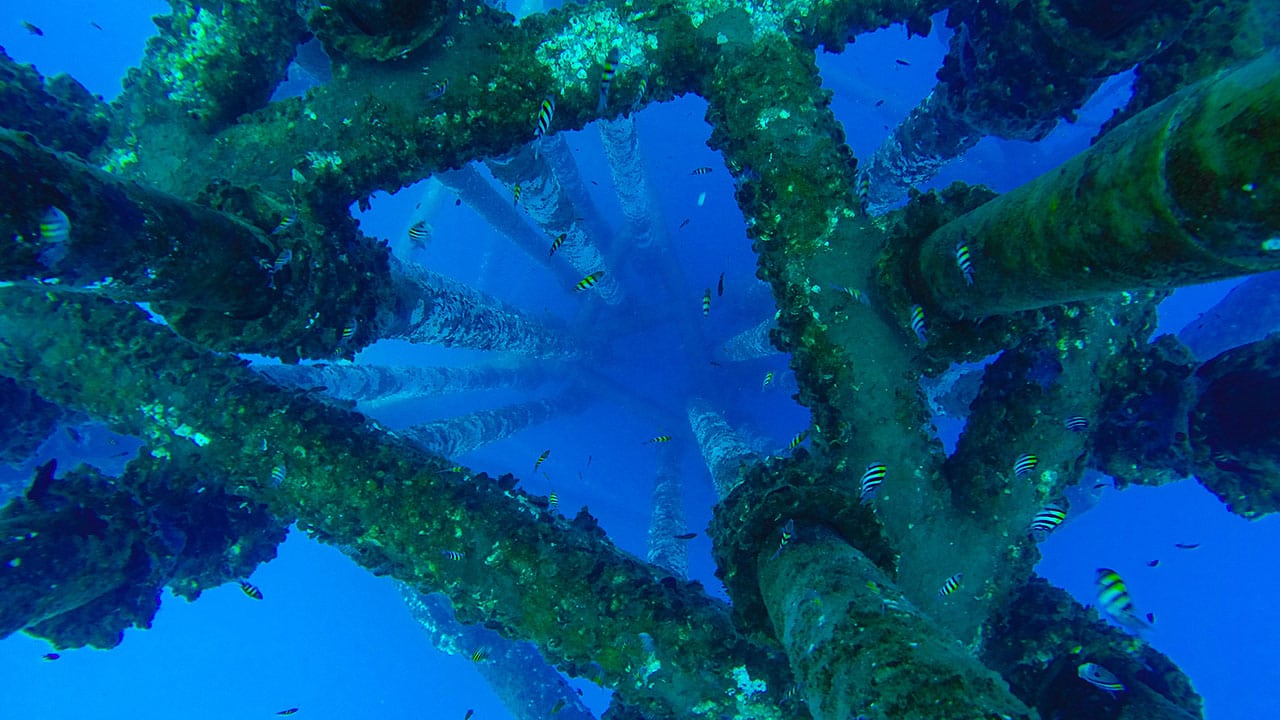

Offshore pipelines are designed in several phases, with much of the early conceptual work focusing on making sure that the route is safe. When planning and selecting a route, design teams must consider the stability of the sea floor, checking to see whether it is flat or uneven. An unstable seabed could put pipelines at greater risk of bending and rupturing. Softer sea beds may also cause problems since pipelines might sink, making maintenance difficult.

Many professionals with process piping training know that offshore pipelines incur great risk from seismic activity, which could cause underwater landslides that can bend and damage pipelines. Strong currents and waves could cause problems as well. For instance, areas with stronger currents, particularly in shallower crossings, could make an offshore pipeline harder to construct and repair later on. Pipeline designers will often avoid areas with a great deal of floating ice, which could scrape or tear open pipelines. An accumulation of ice debris on the sea floor, or underwater vortexes, could also put a pipeline at risk of breaking due to overstress.

Pros with Process Piping Training Help Design Tough and Durable Offshore Pipelines

With so many underwater risks to offshore pipelines, it is important for grads with experience in process piping drafting to help make them strong. Pipeline design teams will consult design codes, such as measures to deal with environmental conditions and loads, for the best ways to keep them safe, strong, and efficient.

Corrosion is a big concern in offshore pipeline design

Offshore pipelines should be constructed from especially strong high-yield strength steel and protected with concrete and fiberglass against scrapes and other damages. Offshore pipelines should also be coated with anti-corrosive chemicals, such as epoxy, or generously lined with cement.

Points to Consider Regarding Offshore Pipe-Laying and Construction

One of the major challenges of offshore pipe-laying is buoyancy. Because of the risk that sections of pipe might break away from the pipeline and float upwards, design teams need to find an effective means of holding everything in place. A few proven methods include covering the pipeline in a heavy layer of concrete or designing pipe sections with greater thickness and diameter to weigh them down. Graduates of process piping specialization courses can become an asset to design teams by simulating pipe-laying procedures to help choose the best method and cut construction times.

Are you ready for a career in process piping?

Fill out the form to find out more!