Computer Aided Manufacturing (CAM) refers to an automation process that accurately converts product design and drawing of an object into a code format, readable by the machine to manufacture the product. The system allows professionals who have completed Computer Aided Design courses to control machinery in a highly automated environment to manufacture various items and pieces. CAM is also used in all computer-aided operations in a manufacturing plant, such as planning, management, transpiration, and storage.

History

CAM evolved from the technology utilized in the Computer Numerical Control machines that were used in the early 1950s, which involved the use of coded instructions on a punched paper tape and could control simple manufacturing functions. Computer Aided Manufacturing is a logical extension of that idea, as it allows for a whole set of manufacturing functions to be controlled simultaneously.

The system’s primary purpose is to speed up the production process of different components with more precise dimensions and material consistency. In some cases, Computer Aided Manufacturing uses only the required amount of raw material, thus minimizing waste and reducing energy consumption.

Practical Applications

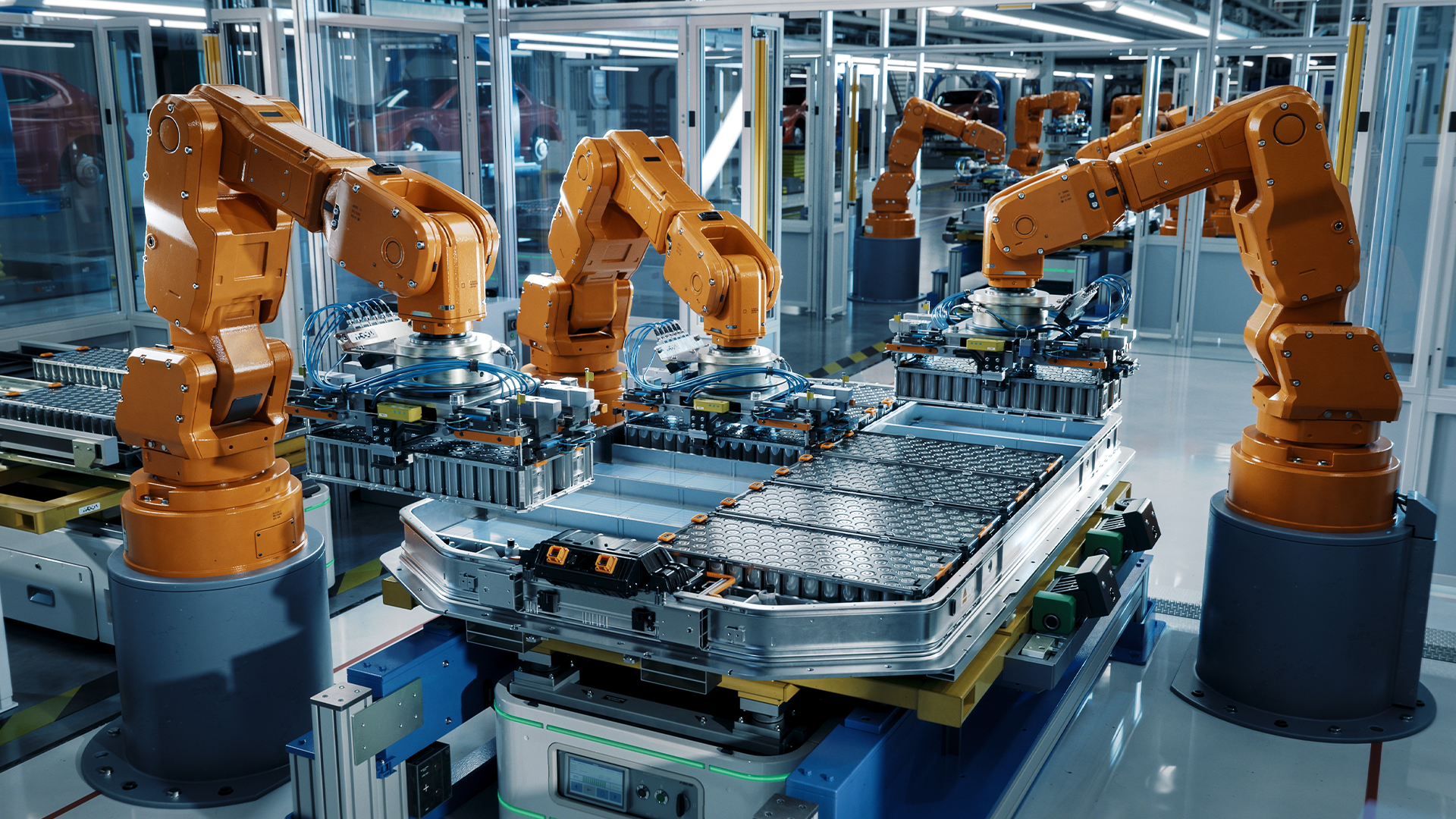

The CAM system controls manufacturing operations performed by robotic welding machines and other industrial tools. A professional with Process Piping Training oversees how the system moves the raw material to different machines after the completion of each step. Finished products are also moved within the system to complete other manufacturing tasks such as synthesizing, quality control, packaging and final checks.

Some of the major applications of the system are woodturning, metalworking, glass working, spinning and graphical optimization of the entire manufacturing procedure. Production of surfaces and screw threads, or aspheric optical elements made from glass, crystals, and other metals, can also be done through Computer-Aided Manufacturing.

Since CAM can manufacture three-dimensional solids using ornamental lathes with great intricacy and detail, its practical applications are nearly endless. The system can construct products like:

- candlestick holders

- table legs

- bowls

- baseball bats

- crankshafts

- camshafts

Benefits of CAM

Computer Aided Manufacturing makes it easier for professionals with Engineering Training to measure a plant’s output and production as a whole as well as to optimize the assembly process. CAM systems can maximize utilization of a full range of production equipment, such as high speed, 5-axis turning machine, and electrical discharge machines, and can help to implement advanced productivity tools like simulation and optimization to leverage specific professional skills.

In fact, one of the key areas of development is the simulation of performance. Among the most common types of simulation are testing a piece or item for response to stress. In stress tests, model surfaces distort as the part comes under simulated physical or thermal stress. The ease with which a part’s specifications can be changed facilitates the development.

CAM can be applied to the fields of mechanical, electrical, industrial and aerospace engineering. Other applications such as thermodynamics, fluid dynamics, electromagnetism, and kinematics are also compatible with Computer-Aided Manufacturing, leveraging the value of skilled professionals that have received excellent training.

Interested in getting started with Digital School? Well, there’s never been a better time!

Click below to schedule a meeting with one of our Admissions Advisors and learn more about how you can earn more money in a career you love – in a year or less!