The engineering field has evolved greatly in the past twenty years. Engineers that have careers that have spanned past twenty years or longer will be the first to share their tales of working without simulation software. Improvements to simulation technology have brought about improvements in the engineering field, and even those with architecture training can benefit from these improvements. You don’t have to only have had engineering training to realize that the benefits and improvements to simulation software help create technological output that until very recently wasn’t possible.

Even though both high-tech or low-end methods of producing engineer output have their pros and cons, the future of engineering simulation will encompass technology that will only improve with time, due to improvements to existing software as well as the growth of the industry. And since one of the greatest benefits of using simulation software is the ability to predict and create innovative products, it’s only natural that the industry will benefit the most from increasingly innovative software.

Encompassing Innovation

According to Daratech, a market research and technology assessment firm in the United States, since simulation technology is the foundation of the output from the engineering industry, companies are investing in engineering simulation at unprecedented levels. Along with this investment, the competitive edge in the development of simulation software is determined by how an organization uniquely applies the technology and integrates it into its product development processes. Although it could be easy for many companies to stick to what they know and use standard existing software, there is the need to be innovative in product designs and create innovative solutions to new problems, which is reflected in how the software is developed. Even those who work in the design industry and have simply taken online CAD courses will be able to appreciate the improvements to simulation technology.

The Future of Engineering Simulation

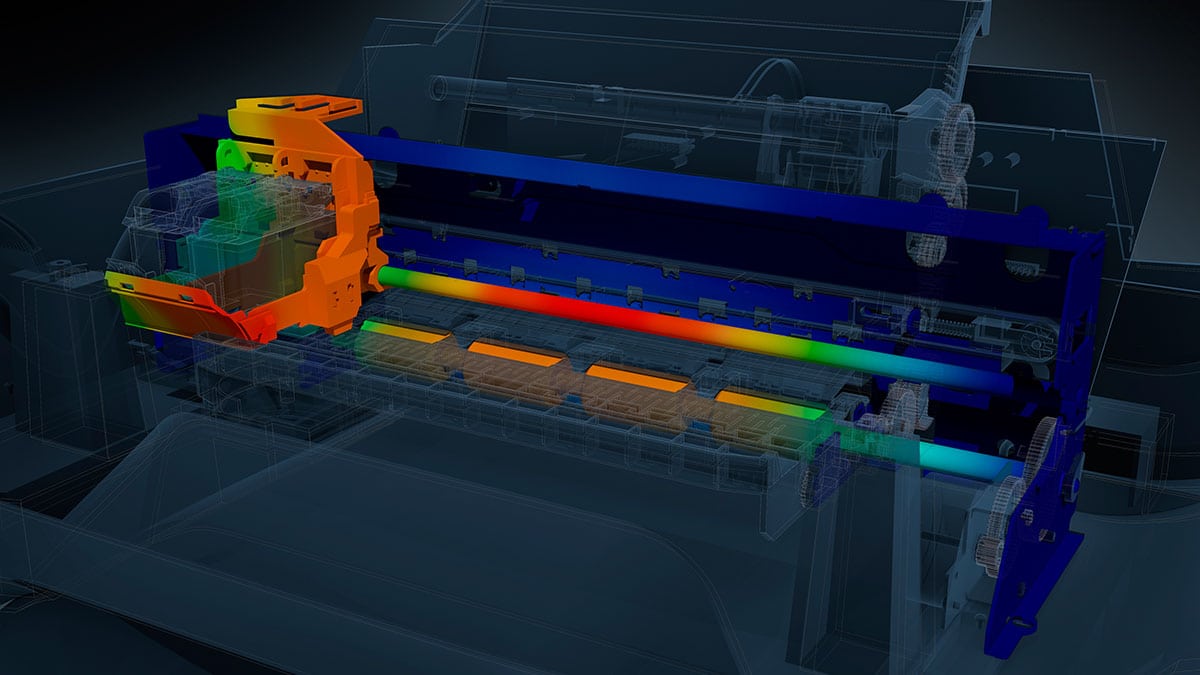

Using simulation software also means that it is possible to virtually test product creations to greatly improve product development. However, one technology that will have a large impact on engineering simulation is additive manufacturing. Since additive manufacturing is primarily used in prototyping and 3D printing, simulation technology has basically come full circle, where using 3D printing makes it possible to create physical prototypes, as was done in the pre-simulation software technology era.

Another example of technology that is making improvements to simulation-based engineering is COMSOL Multiphysics, cross-platform software which offers to program, preprocessing and post-processing possibilities to improve workflow from design study to prototype. A few examples of projects where COMSOL has been used include beam-steering, meta-materials satellite antenna, TerraPower nuclear reactor conceptual design, and a cold storage device for the distribution of the vaccine.

Finally, in order to constantly stay ahead of the curve in engineering simulation, it is necessary for engineers to always be researching and learning new ways to integrate cutting-edge technology into their work. The constant innovation of the technology used in the field will help engineers design and develop better products.

To learn more about innovations in 3D printing, check out this video below to learn more about the future of the industry: http://phys.org/news/2013-10-future-d.html