Reverse engineering has been used throughout history to analyze and adopt an enemy’s weapons, to appropriate or improve upon another’s technology or any other action of taking something apart and putting it back together. Reverse engineering technology has, over the last decade, become a practical tool to create a three-dimensional virtual model of an existing physical part. Hardware and software have become more affordable, including scanners and other hardware used to input measurements, helping engineering companies speed up development and cut production costs. That, in turn, has made 3D computer-aided design, as learned in CAD School, much more flexible, unlocking exciting new possibilities in the fields of engineering, manufacturing and more.

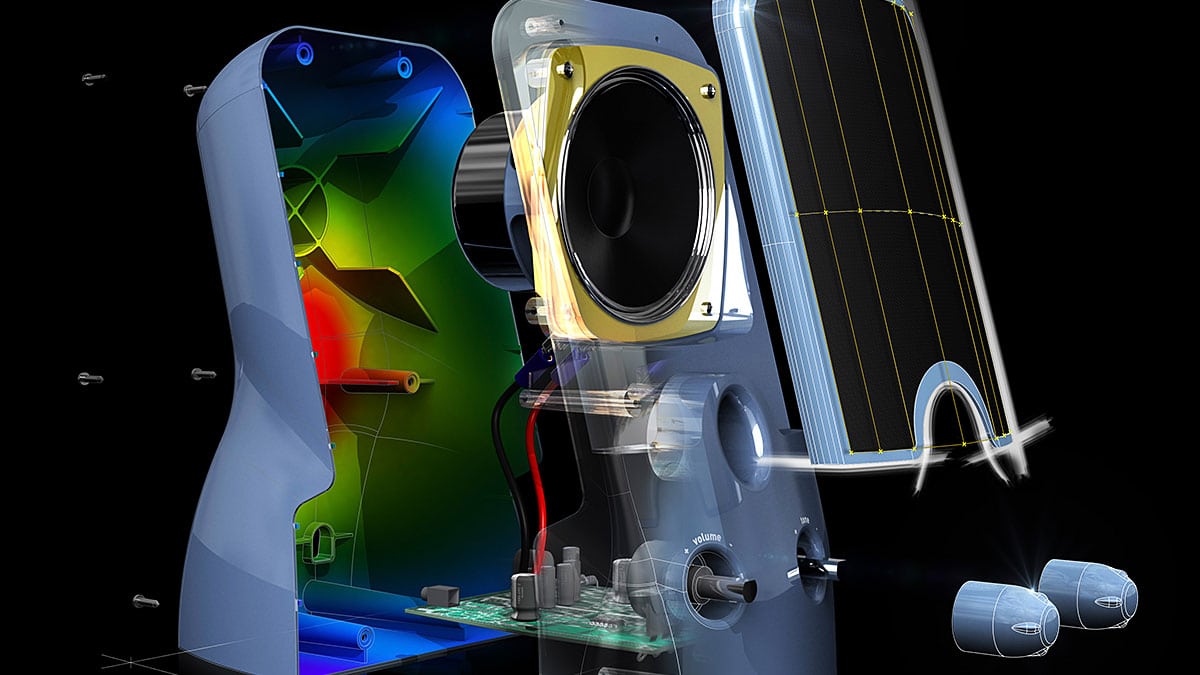

To be able to reverse-engineer an item, a designer with CAD training needs compatible hardware and software. The hardware’s role is to measure an object with extreme precision, using advanced scanning technologies like a coordinate measuring machine, computed tomography, laser scanner or a structured light digitizer. The software’s role is to use those measurements to reconstruct the item as a 3D model.

Why reverse-engineer an item?

There are many different reasons to explain why a company would want to reverse-engineer an item. Some of these reasons include:

- Interoperability

- Product analysis

- Digital update and correction

- The technical documentation of a particular device doesn’t exist anymore

- Security or quality auditing

- Academic and learning purposes, such as in a CAD College

Reverse engineering is also used by businesses to bring existing physical products into digital environments, to make a digital 3D record of their own products or simply to assess a competitor’s product. The technology can be used to analyze how a product works, what it does, how its components interact and to estimate production costs. This process can provide extremely useful information on a competitor’s product, which can then guide creative and business decisions.

Surprising new uses

Though these tools were primarily designed with manufacturing objects in mind, engineers are finding surprising new uses for them. Some firms are using reverse-engineering hardware and software to measure performance over time. For example, imagine a brand new industrial pump. Now, imagine the pump a year later, producing slightly less volume than the original model due to wear and tear. Thanks to reverse-engineering, the engineers can scan and produce a CAD model of the worn-out pump and compare it to the original model, to figure out what parts are vulnerable and what caused the drop in performance.

The wider availability of handheld scanners, which are now smaller, more affordable and easier to use, is also proving to be useful to many different types of industries. The archaeology community, for example, has started using handheld scanners for its own needs. Because handheld scanners can digitize 3D surfaces in real time, connect to a laptop computer via a FireWire cable and input that information into a CAD system, archaeologists are now able to use scanners in the field, even if it’s to scan large objects. These devices are very helpful and greatly accelerate the reverse engineering process.