Toy design is a fun and lucrative career that professionals with engineering skills and imagination may not have thought to pursue. Over the years, children’s toys have become more sophisticated, requiring a greater attention to detail when designing those with many different components. Engineering design skills, such as 3D modeling, can be an asset for toy companies that need to increase production, cut costs, and meet the demands of their customers within a narrow timeframe.

There are many ways engineering design technicians can use their technical skills to help design toys. Want to learn more about how these skills can apply to the toy industry? Read on!

Engineering Design Technicians Can Use Autodesk Inventor to Help Toy Designs

Autodesk Inventor has helped professionals plan to design a wide variety of products. For students looking for a career in engineering design technology, this software could offer a great way to help design new toys. For intricate toys with many components that all need to fit together properly, this approach can be an especially beneficial time saver.

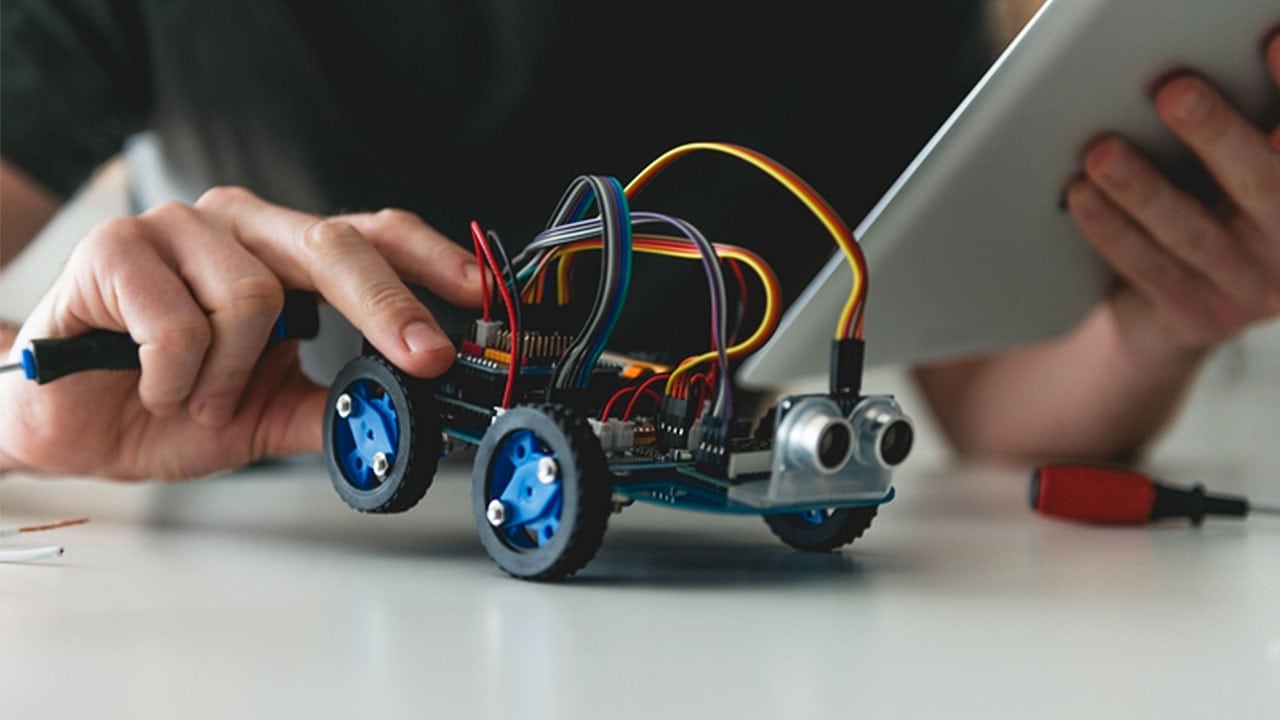

For example, in 2017, LEGO’s design teams created a robot-like toy called the BOOST robot. The BOOST is made from 847 individual Lego bricks and has a battery mini sensor that allows it to be controlled remotely from a tablet. Inventor could provide an ideal digital environment to help accurately model complex toy concepts such as this.

Inventor could help to model the multiple interconnected parts of a toy, and how they’re meant to function as a whole. With so many pieces to consider, professionals may also be able to help design teams discern the best places to put the wires and gears that allow a complex toy to move once assembled. With Inventor, the possibilities of toy design could be determined by the limits of one’s imagination!

Collision Detection Can Help Toy Designers Efficiently Spot Design, Flaws

Collision detection is a feature of Autodesk Inventor that graduates of an engineering design technology program know all about. This feature allows engineering design technicians and other design professionals to see potential design problems. In the case of toys, like Hasbro’s popular Transformers line, spotting design flaws can be important to creating a successful product.

Hasbro’s Transformers can serve many different functions, starting off as a vehicle, animal, or dinosaur and “transforming” into a robot action figure by manipulating the toy’s various parts.

In order for these toys or others like them to function properly, pieces need to fold and fit in a way that allows it to shift between two alternate modes. Inventor’s collision detection can alert design teams if certain parts of a toy prevent others from opening or closing properly. Design teams can thus quickly get to work addressing any flaws to make sure they’re providing the best product possible.

Graduates with Engineering Training Could Help Cut Prototyping Costs

Prototyping is an important part of toy design. It involves creating a physical product that can give design teams an idea of whether the product works or doesn’t. Oftentimes, it is even tested out among focus groups to determine if the design fully addresses the needs of potential clients. But do companies need to create a physical prototype at all?

Prototyping is one of the most important steps in toy design

Designing with user experience in mind could help toy companies gather data on their clients’ motivations and needs before making a prototype. Part of this process involves interviewing clients and gathering data on what consumers want from a product. Graduates of engineering training can then use this data in to help design the right toy from the get-go. This, in turn, could help improve productivity and possibly cut down on prototyping costs. In this way, engineering design technicians provide valuable options that help speed up production and create fun new toys for kids to enjoy!

Are you ready to prepare for a toy design career as an engineering design technician?

Fill out the form to get started!