Have you seen what 3D printers can do? Drawing on years of technological innovation, these machines can now manufacture finely detailed objects with fascinating precision in a matter of minutes.

That’s why today’s computer-aided design (CAD) professionals use 3D printing to bring many of their own architectural design ideas to life. If you’re interested in becoming a CAD or AutoCAD professional, you’ll be able to design and create a wide range of projects with the help of 3D printing technology.

But how do these machines work? What can CAD technicians do with them? And how does a modern CAD technician choose which printer is right for each particular project?

There are three main kinds of 3D printers, and each offers unique benefits to the modern CAD student:

1. Stereolithography: A Trusted Standby for AutoCAD College Students

When you imagine a 3D printer, you probably think of the most popular 3D printing technology, stereolithography (SLA), even if you don’t know it by name.

SLA is a laser-based process that works with photopolymer resins to form solids in ultra-precise ways. Anywhere the lasers touch becomes solid resin, allowing designers to produce finely detailed parts.

‘Invisalign’ plastic teeth retainers are now often made with stereolithography 3D printing.

As you might expect, the mechanics of this process are complex. To start, the photopolymer resin is held in a vat with a movable platform inside. A laser beam is directed across the surface of the resin in accordance with the 3D data supplied to the machine by CAD technicians, and the resin hardens precisely where the laser hits it.

Once that initial layer is completed, the platform shifts and the next layer is sliced out. This pattern continues over and over until the final layer has been cut when the entire vat can be taken out of the machine and the object removed.

The precise nature of this method has made SLA the first widely-recognized and commercialized means of 3D printing, used and respected in many of the world’s top CAD design courses.

2. Fused Filament Fabrication: An Affordable 3D Printing Option

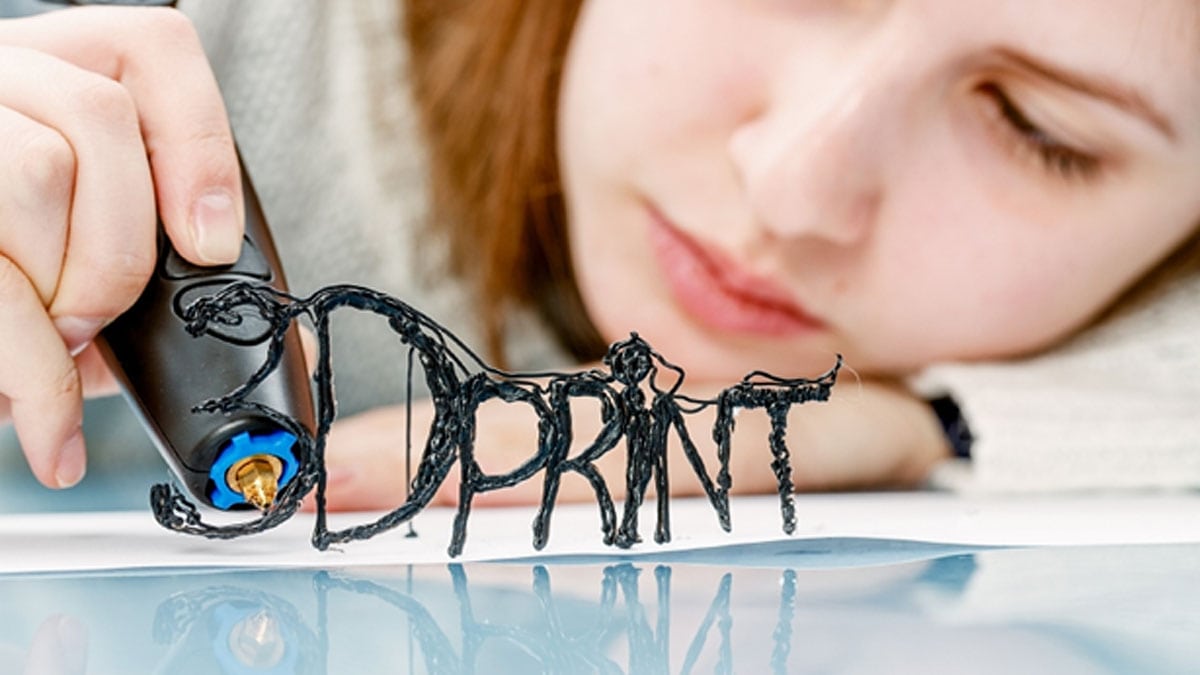

Fused Filament Fabrication (FFF) is a 3D printing process that extrudes a strand of molten plastic thread to shape and build an object.

This technology is much simpler that SLA, involving a pen-like nozzle that designers can control as the machine extrudes the hot plastic filament. Think of a hot glue gun, but with quickly-hardening and long-lasting plastic instead of glue.

A design technician uses Fused Filament Fabrication 3D printing technology.

FFF machines usually cost about $300 and use relatively cheap plastic strands. While easily accessible for craft hobbyists, these printers are not recommended for those in AutoCAD college, because of their particular weaknesses: According to the AutoCAD software company, FFF’s “production speed, flexibility, and surface finish” don’t quite measure up to “more accurate, more expensive methods.”

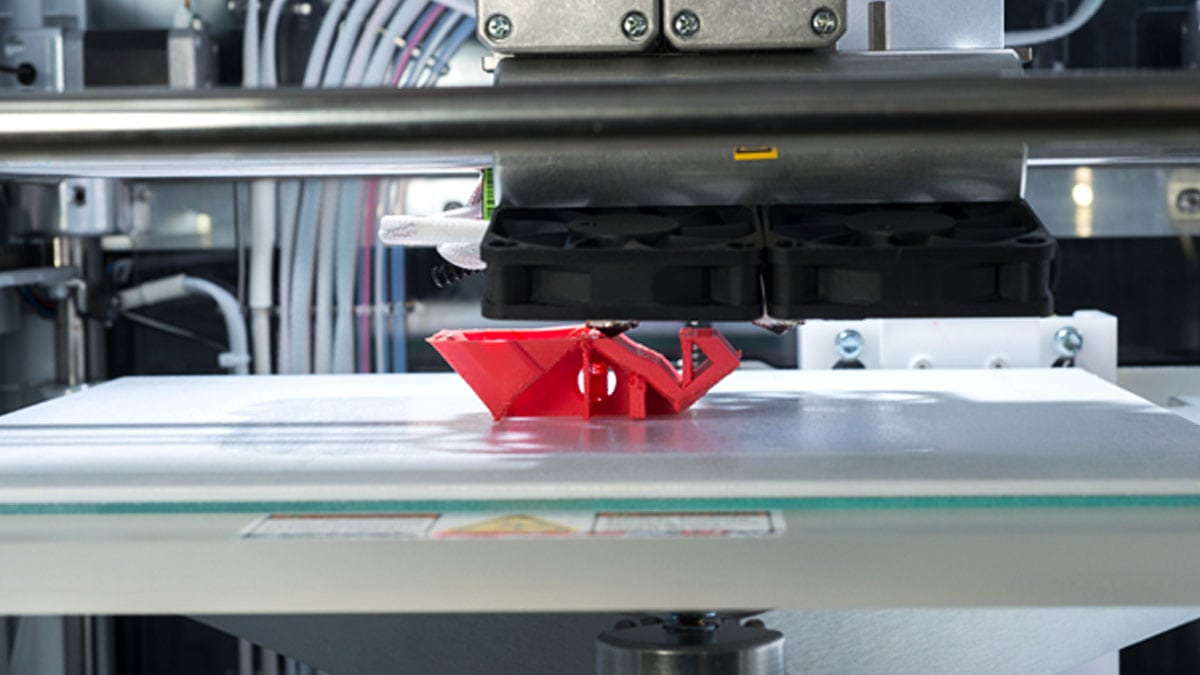

3. Selective Laser Sintering: Most Accurate Method, According to AutoCAD

Selective Laser Sintering (SLS) is one of the newest forms of 3D printing, done by compacting loose material into solid shapes using sudden and intense heat. The standard materials involved in SLS printing are powdered nylon-based plastic and (as in SLA) high-powered lasers.

A Selective Laser Sintering (SLS) 3D printer in action.

The AutoCAD company calls SLS “by far the most accurate 3D printing method,” yet also recognizes that SLS 3D printers are too costly for the average hobbyist (machines cost upwards of $10,000). But CAD professionals with access to SLS can use it to create precision molds, parts, and even print in custom colours.

With innovations like these, CAD students and professionals can trust that this 3D printing technology will continue to improve in the coming years—becoming even more accessible, affordable, and better capable of turning CAD design ideas into realities.

Are you interested in pursuing state-of-the-art 3D CAD training?

Visit Digital School for more information about starting your own creative career.